Robotics & Automation Lead Engineer-Tester

4.8 out of 5 based on 8363 reviews.

#Program

About Program

QP Name: Robotics & Automation Lead Engineer-Tester

QP Code: CSC/Q

QP Version: 1.0

NSQF Level: 6

Model Curriculum Version: 1.0

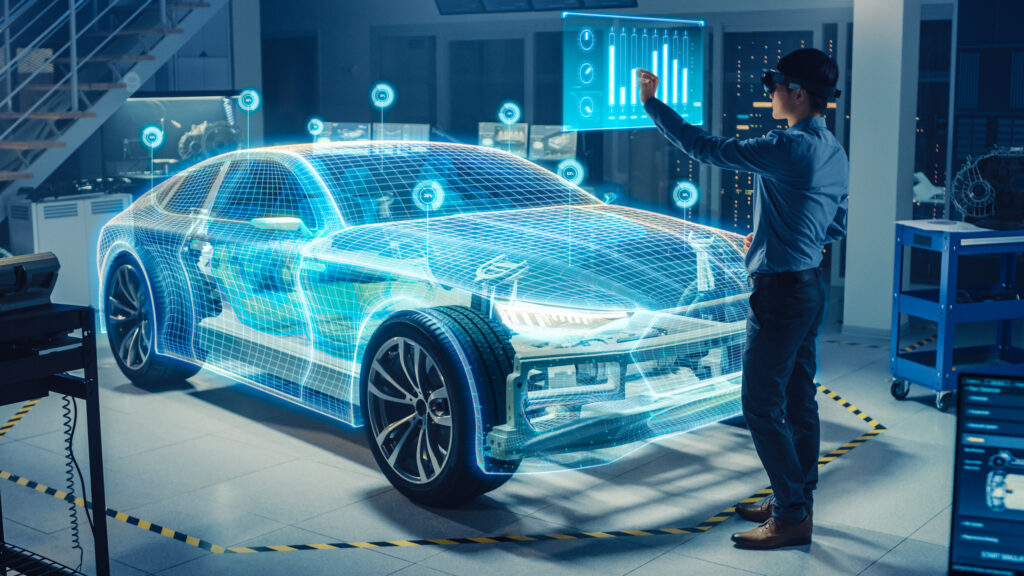

A Robotics & Automation Lead Engineer – Tester is responsible for designing, testing, and validating robotic and automation systems in industrial applications. This role ensures that robotic systems meet performance, safety, and reliability standards before deployment. The engineer works with industrial robots, PLCs, sensors, AI-driven automation, and IoT systems to evaluate system efficiency, detect faults, and optimize robotic workflows.

#Bookdetails

Module

Module 1

Introduction to Robotics & Automation

Module 2

Robotics and Automation Fundamentals

Module 3

Robotics and Automation System Design & Installation

Module 4

Robotics & Automation System Integration

Module 5

Industrial Networking & Protocols

#Overview

Program Overview

Training Outcomes:

At the end of the program, the learner should have acquired the listed knowledge and skills.

– Robotics and Automation Fundamentals: Develop a solid understanding of the

principles, concepts, and technologies underlying robotics and automation systems,

including sensors, actuators, control systems, kinematics, dynamics, and artificial

intelligence (AI).

– Programming Proficiency: Gain expertise in programming languages commonly used

in robotics and automation, such as Python, C/C++, MATLAB, or ROS (Robot

Operating System). Learn to develop, debug, and optimize software for controlling

robotic systems.

– System Design and Integration: Acquire skills in designing, architecting, and

integrating complex robotics and automation systems. Learn to select appropriate

hardware and software components, develop system architectures, and ensure

interoperability and compatibility between subsystems.

– Simulation and Modeling: Learn to use simulation tools and software (e.g., Gazebo,

V-REP, Simulink) to model, simulate, and validate the behavior of robotic systems in

virtual environments. Understand how to conduct virtual testing, optimization, and

scenario analysis.

– Testing and Validation Techniques: Master various testing methodologies, including

unit testing, integration testing, system testing, and acceptance testing, tailored for

robotics and automation systems. Learn to develop test plans, execute tests, analyze

results, and verify system performance against specifications and requirements.

– Safety and Compliance: Understand safety standards, regulations, and best practices

relevant to robotics and automation, such as ISO 10218 (Robots and Robotic Devices)

and ISO 13849 (Safety of Machinery). Learn to assess and mitigate safety risks

associated with robotic systems and ensure compliance with applicable regulations.

– Troubleshooting and Root Cause Analysis: Expertise in diagnosing and resolving

issues that arise during additive manufacturing processes. Skill in conducting root

cause analysis, implementing corrective actions, and preventing recurrence of

problems.

| NOS and Module Details | Theory Duration | Practical Duration | On-the-Job Training Duration (Mandatory) | On-the-Job Training Duration (Recommended) | Total Duration |

|---|---|---|---|---|---|

| Bridge Module: | 05:00 | 00:00 | 00:00 | 00:00 | 05:00 |

| Module: 1 Introduction to Robotics & Automation | 05:00 | 05:00 | |||

| CSC/N: Selection and installation of Robotics & Automation Systems | 30:00 | 60:00 | 00:00 | 00:00 | 90:00 |

| Module:2 Robotics and Automation Fundamentals | 10:00 | 30:00 | 00:00 | 00:00 | 45:00 |

| Module:3 Robotics and Automation System Design & Installation | 15:00 | 30:00 | 00:00 | 00:00 | 45:00 |

| CSC/N: Integration of Robots and Automation Systems using Industrial Networking Protocols | 34:00 | 56:00 | 60:00 | 00:00 | 150:00 |

| Module:4 Robotics & Automation System Integration | 12:00 | 36:00 | 30:00 | 00:00 | 78:00 |

| Module:5 Industrial Networking & Protocols | 22:00 | 20:00 | 30:00 | 00:00 | 72:00 |

| CSC/N: Testing & Maintenance of Robotics & Automation System | 36:00 | 84:00 | 90:00 | 00:00 | 210:00 |

| Module:6 Robotics & Automation Safety Testing and Procedures | 26:00 | 40:00 | 30:00 | 00:00 | 96:00 |

| Module:7 Maintenance & Troubleshooting Techniques | 10:00 | 44:00 | 60:00 | 00:00 | 114:00 |

| Module 8: Introduction to Employability Skills | 1:00 | 2:00 | 00:00 | 00:00 | 3.00 |

| Module 9: Constitutional values - Citizenship | 0.5:00 | 1:00 | 00:00 | 1.5:00 | |

| DGT/VSQ/N0103 Employability Skills (90 hours) NOS Version No. – 1.0 NSQF Level – 5.5 | 36:00 | 54:00 | 90:00 | ||

| Module 10: Becoming a Professional in the 21st Century | 2:00 | 3:00 | 5:00 | ||

| Module 11: Basic English Skills | 4:00 | 6:00 | 10:00 | ||

| Module 12: Career Development & Goal Setting | 1.5:00 | 2.5:00 | 4:00 | ||

| Module 13: Communication Skills | 4:00 | 6:00 | 10:00 | ||

| Module 14: Diversity & Inclusion | 1:00 | 1.5:00 | 2.5:00 | ||

| Module 15: Financial and Legal Literacy | 4:00 | 6:00 | 10:00 | ||

| Module 16: Essential Digital Skills | 8:00 | 12:00 | 20:00 | ||

| Module 17: Entrepreneurship | 3:00 | 4:00 | 7:00 | ||

| Module 18: Customer Service | 4:00 | 5:00 | 9.00 | ||

| Module 19: Getting ready for apprenticeship & Jobs | 3:00 | 5:00 | 8:00 | ||

| Module 20: Collaboratively coordinate with the team | 30:00 | 60:00 | 90:00 | ||

| Module 21: Maintain Health, Safety and Environment at workplace | 10:00 | 20:00 | 30:00 | ||

| Total Duration | 176:00 | 334:00 | 150:00 | 660:00 |

#TRY NOW

Improve Your Skills

Enjoy our course content

Contact us

for more information

#TrainerInfo

India's Leading Trainers.

Mehek Gunjan

IIT Delhi

Kailash Biswa

IIT Kanpur

Debika Roy

Harvard University

Praful Modak

IIT Bombay